The Co-op Case Study

Removing all bisphenols from receipts.

The Co-op – Acting on the ‘Everywhere Chemicals’, bisphenols, ahead of legislation

The Co-op are known for their commitment to environmental sustainability and in 2019, they began discussions with Fidra regarding bisphenol-free receipts. Recognising that so called ‘everywhere chemicals’, bisphenols, are a chemical group with the potential to harm both people and the environment, the Co-op were keen to avoid regrettable substitution of bisphenol-A (BPA), following its EU-wide ban in thermal paper, with another damaging bisphenol.

Iain Ferguson, Environment Manager for the Co-op, explains how and why they moved to bisphenol-free receipts.

What led the Co-op to remove all bisphenols from receipts?

The Co-op has a strong track record of dealing with chemical issues based on evidence and best practise. We looked at the issues of BPA in the same light. We took note of the evidence emerging on BPA in till receipts (and other thermal printed paper). One of the possible alternatives to use, which would have reduced the extra costs we faced in switching out of BPA, was BPS. It was of concern to us that BPS is so close an analogue of BPA that we would expect the same health effects to be present in its use. Our change form BPA to phenol-free in till receipts was not just about protecting the public; we were very concerned with protecting the health of our store staff who handle thousands of till receipts each day.

What did the process of switching to bisphenol-free paper involve?

The process of changing policy at the Co-op involved collating information about the health concerns associated with BPA, the similar chemistry of BPS, the financial implications of the various options and the potential ways to mitigate that additional cost. We also highlighted the clear potential for BPS to face a similar ban in future. The leaders at the Co-op readily accepted the need to move to a phenol-free solution to protect customers and staff.

How did the Co-op mitigate additional costs?

Mitigation of extra cost was through changing the practice in store away from automatically giving customers a till receipt, to asking customers if they need one. This extends to self-scan checkouts which give customers 5 seconds to that they do want a receipt; the default position is no receipt. This has additionally helped us to reduce paper waste for till receipts, and we have reduced our paper usage by 45% overall and 58% on self-scan checkouts. Customer’s rights are not affected by this change.

Fidra’s work on bisphenols

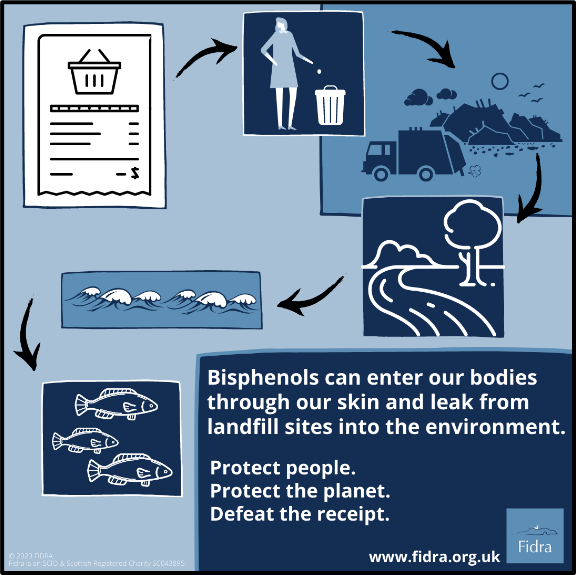

Fidra’s bisphenols project has seen major UK retailers and food outlets commit to removing all bisphenols from their receipts. Fidra are now calling for group-based legislation to ban all bisphenols from use in receipts. Restricting all bisphenols in thermal paper will help protect people and the environment from endocrine disrupting chemicals, as well as creating a level playing field for all businesses.

Visit our bisphenols webpage for more.