The first artificial pitch surface was called ‘Chemgrass’ which came on the market in 1965. Since then, artificial grass has become increasingly popular for sports and landscaping. The number of full-size artificial sports pitches in Europe grew threefold between 2006-2012, with the help of 3G technology, and new pitches continue to be built year on year [1].

A local sports pitch is a great opportunity for outdoor play, whether it’s natural or synthetic. But did you know that 3G artificial pitches can also release microplastic to the environment? And what happens to the old pitch when it needs to be replaced?

Microplastic from artificial pitches

Many artificial sports pitches use third generation (3G) technology, which means fine granules, usually made of rubber, are added as a performance infill to make a more comfortable playing surface. These loose granules sit in between the strands of ‘grass’ filaments on the top of the carpet. The use of infill is especially important for contact sports like football and rugby to reduce injury risk.

The most common performance infill is made of a synthetic rubber called Styrene Butadiene rubber (SBR). However, other materials can also be used as infill, including other types of plastic and organic alternatives like cork or wood. Nevertheless, SBR ‘rubber crumb’ is used on the majority of pitches. It is produced by grinding up old vehicle tyres that have reached their end of life as a tyre.

If you’ve ever played on a field like this you’ll probably notice the little granules turning up in your shoes, or in your kit. Not only do they end up in your bags and sports clothing, they can also escape from the edges of the pitch, down drains, into local water sources and surrounding soils. Microplastic can also be lost during installation and removal of pitches, in handling and refilling of infill, and leaks can continue even after the pitch has been thrown away.

How much is lost?

Though current estimates of infill loss are uncertain, it is clear that significant losses do occur.

For an average sized pitch, rubber granules need to be topped up around 1 to 5 tonnes each year, which is around 1-4% of the total rubber crumb on the pitch. This amounts to approximately 72,000 tonnes of ‘lost infill’ across Europe every year.

It is difficult to know exactly how much of this ‘lost granule’ ends up in the environment but microplastic loss is well documented. Field studies show large variation across pitches, however on average about 10% ends up down drains (~900-8000 tonnes of granules), in stormwater and local watercourses, while almost half is likely to build up in nearby soil and grass (8000-32500 tonnes per year) [2]. In fact, a field study in the Netherlands found up to 70kg per year entering nearby water courses from a single pitch [3]. It is also true that some will also end up in municipal waste or compacted into the base of the pitch.

Toxic leaching

The most common type of performance infill is rubber, which is usually made from ground up old car and lorry tyres. The rubber, and other types of plastic performance infill, can contain quantities of potentially harmful chemicals and heavy metals. End of life tyre rubber is known to have hazardous chemicals ranging from bisphenol A to polyaromatic hydrocarbons (PAHs) [4], and the properties of this ‘micro-rubber’ mean they are more likely to associate with persistent organic pollutants in the environment [5].

These chemical can leach out over time, and will continue to escape from granules sitting on the pitch, in soil or water. Studies show that zinc, associated with old tyre rubber, can leach from fields in quantities that harm the environment [6-7]. Laboratory studies further show how these leached chemicals, as well as the particles themselves, can harm animals in both soil and water environments. Development of chicken embryos [8], response in earthworms [9] and effects on freshwater fish [10] have all been studied.

Due to the hazardous substances in tyre rubber used on pitches, media interest has focused on human health concerns. Some of the chemicals present, including PAHs – Polycyclic aromatic hydrocarbons, are well known as carcinogens, which at certain exposure levels can pose a threat to the health and well-being of humans[4].

The European Chemical Agency, ECHA assessed whether the presence of such substances posed health risks to the general population, in 2017. The results of this assessment and other scientific studies indicate that there is a very low level of concern from exposure. In 2017 Health Protection Scotland reviewed all the health evidence and concluded in their summary that there is:

‘ …a clear consensus in evidence published to date, which does not support the hypothesis that exposure to tyre crumb used in artificial surfaces poses a significant risk to human health’.

ECHA have confirmed that they will continue to look at the health and environmental impacts of other substances contained in these granules. In 2021 the ECHA Risk Assessment Committee looking into the risks plastic particles (including rubber crumb) posed to human health concluded:

‘Leaching from plastic particles could present a longterm source of chemicals into tissues and body fluids, plastics additives of concern include phthalates, BPA, brominated flame retardants, triclosan, bisphenone and organotins. Additional research is required to adequately assess the risks that accumulation of micro- and nanoplastics in the body may pose…’

Find out more on our blog on Turf, Tyres & Health

Disposal of Artificial Pitches

Artificial pitches should be replaced every 8 to 10 years, to ensure a safe and comfortable playing surface. This creates a problem; what do you do with a pitch when it is removed?

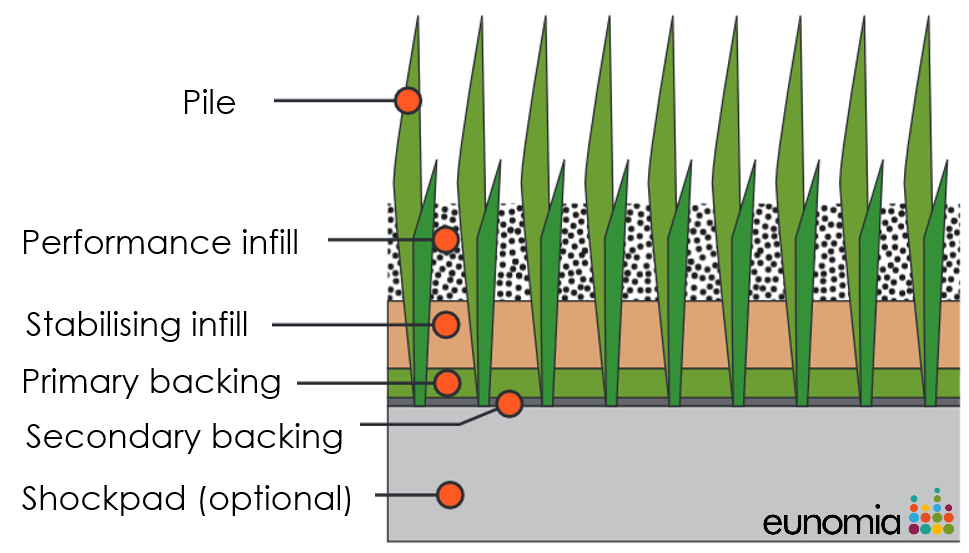

An artificial turf pitch is made up of different layers. These layers are made of different types of plastic, rubber, and other materials. The mix of materials means there is no easy way to recycle the entire pitch and even harder to know how to dispose of the pitch when it can no longer be used; particularly as shredded rubber granules from tyres are banned from landfill.

New advances in technology are making it easier to recycle pitches, but there is currently only one company across Europe that can effectively recycle 3G pitches into new products. New technology can lift out, shred and sort pitches, letting 99% material be reused or recycled [11] .

As a result, stockpiling, illegal disposal and misleading ‘recycling services’ [12-13] can lead to more environmental problems. This can include plastic pollution from disintegrating carpet, mountains of discarded infill releasing microplastic dust, and even toxic fires [14].

To avoid further environmental problems, which are rapidly increasing considering the lack of widespread infrastructure to deal with artificial pitches currently in use, we are calling for all pitches to be installed with a clear end-of-life plan in place.

What is Fidra doing?

At Fidra, we want to ensure both new and existing pitches are being designed, maintained and used without having a big impact on the environment. This means encouraging microplastic-free pitches, making sure plastic stays on the pitch where used and sensible reuse or recycling at the end of its life.

Take Action

Use sports pitches and want to pitch in to prevent plastic pollution?

Do you own, design or manage pitches and want to do your bit to prevent pollution?

Do you have comments, suggestions, or want to find out more? Get in touch by e-mailing info@fidra.org.uk

References:

[1] Eunomia Research & Consulting (2018) Investigating options for reducing releases in the aquatic environment emitted by (but not intentionally added in) products. Report for DG Environment of the European Commission

[2] Eunomia (2018)

[3] Weijer, A., J. Knol, and U. Hofstra, 2017, Verspreiding van infill en indicatieve massabalans. Rapport i.o.v. BSCN i.s.m. gemeenten Rotterdam, Utrecht, Amsterdam en Den Haag, I. SWECO, 48 pages.

[4] Sicco H. et al. (2019) Chlorinated Paraffins in Car Tires Recycled to Rubber Granulates and Playground Tiles. Environmental Science and Technology, 53 (13) 7595-7603

[5] Halle L. et al. (2020) Ecotoxicology of micronized tire rubber: Past, present and future. Science of the Total Environment

[6] Verschoor, A. (2015) Leaching of zinc from rubber infill on artificial turf (football pitches), RIVM report 601774001/2007

[7] Cheng, H., Hu, Y., & Reinhard, M. (2014). Environmental and health impacts of artificial turf: a review. Environmental science & technology, 48(4), 2114-2129.

[8] Xu et al. (2019) Artificial turf infill associated with systematic toxicity in an amniote vertebrate. Proceedings of the National Academy of Sciences of the United States of America, 116 (50) 25156-25161

[9] Pochron et al. (2017) The response of earthworms (Eisenia fetida) and soil microbes to the crumb rubber material used in artificial turf fields. Chemosphere, 173, 557-562. 10.1016/j.chemosphere.2017.01.091

[10] Kolomijeca, A. et al. (2020) Increased temperature and turbulence alter the effects of leachates from tire particles on fathead minnow (Pimephales promelas) Environmental Science and Technology

[11] E.g. Re-Match Turf Recycling, Denmark: http://re-match.dk/

[12] Zembla (2018) What happens to plastic and polluting artificial turf?

[13] E.g. loose ‘recycled rubber crumb’ offered as playground or animal substrate https://www.chapsmithservices.co.uk/synthetic-surfaces-astroturf-removal-and-disposal/

[14] See notes to specific fires in California & Washington in this US blog article.